Swift Tahoe Instrument Cluster Repair: Fixing Gauge Malfunctions Today

Swift Tahoe Instrument Cluster Repair: Fixing Gauge Malfunctions Today

Blog Article

Discover Top Techniques for Reliable Car Tool Cluster Fixing and Maintenance

In the world of automobile upkeep, the detailed system of a tool collection plays an important duty in providing chauffeurs with vital info regarding their automobile's efficiency. Keep tuned to reveal the leading methods that can enhance the procedure of automobile instrument collection repair and maintenance, ultimately enhancing your driving experience and lorry efficiency.

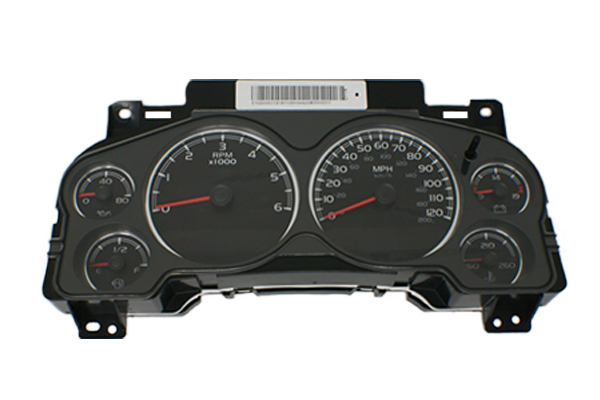

Common Instrument Collection Issues

Some typical issues may arise with lorry instrument clusters, influencing their functionality and precision. This issue can be created by a defective fuel degree sensor or a malfunctioning scale collection. These problems can impede the chauffeur's capacity to keep an eye on vital lorry information, emphasizing the relevance of timely instrument cluster repair service and maintenance to make sure ideal functionality and accuracy while driving. tahoe instrument cluster repair.

Crucial Devices for Fixing

When addressing common tool collection concerns such as malfunctioning speedometers, unresponsive fuel determines, or dim dashboard lights, having the necessary devices for fixing is important in making certain accurate and efficient diagnostics and upkeep. Among the primary tools required for auto tool collection repair are an electronic multimeter for screening voltage and resistance degrees, a welding torch for repairing loose connections or faulty components, and a collection of screwdrivers for taking apart the cluster. Additionally, specialized tools like collection elimination hooks might be needed for safely removing the cluster from the control panel.

Analysis Strategies for Troubleshooting

Utilizing innovative diagnostic strategies is essential in successfully troubleshooting problems within automobile tool clusters to determine and deal with hidden issues properly. By following organized diagnostic treatments and interpreting analysis results precisely, service technicians can enhance the troubleshooting procedure and make certain the correct performance of the instrument cluster. A detailed analysis technique not just saves time but additionally advertises precision in recognizing anchor and fixing tool collection problems immediately.

Cleaning and Upkeep Tips

Software Application Updates and Calibration

Calibration is an additional essential aspect of maintaining your car instrument collection. This procedure includes changing the setups and specifications within the software to make sure that the shown details, such as rate, fuel level, and temperature, is reliable and accurate. Appropriate calibration not just enhances the user experience yet likewise adds to safety and security when traveling by providing vehicle drivers with reputable and accurate information.

To ensure that your vehicle instrument cluster functions ideally, it is advised to adhere to the supplier's guidelines pertaining to software program updates and calibration intervals. By remaining proactive in these areas, you can maximize the effectiveness and lifespan of your tool collection.

Verdict

Finally, effective vehicle instrument cluster fixing and maintenance need a complete understanding of typical concerns, crucial tools, diagnostic techniques, cleaning up approaches, and software updates. By using these methods, specialists can effectively repair and resolve instrument collection issues, guaranteeing reputable and precise efficiency of the automobile's dashboard display screen. Regular maintenance and calibration are vital to stopping future problems and making certain the correct functioning of the tool cluster.

When addressing common tool cluster concerns her response such as malfunctioning speedometers, unresponsive gas assesses, or dim control panel lights, having the necessary tools for repair service is essential in making certain precise and reliable diagnostics and maintenance. Amongst the primary devices needed for auto instrument cluster fixing are a digital multimeter for screening voltage and resistance degrees, a soldering straight from the source iron for repairing defective parts or loose links, and a collection of screwdrivers for disassembling the collection. In addition, specialized tools like cluster elimination hooks might be needed for securely removing the cluster from the dashboard.

In final thought, reliable automobile tool cluster repair work and maintenance need a comprehensive understanding of typical concerns, vital devices, analysis strategies, cleaning methods, and software application updates. Normal upkeep and calibration are key to avoiding future problems and making certain the correct performance of the instrument cluster.

Report this page